Step 4 of designing in this series is just knitting. Knitting, adjusting my draft pattern, adjusting numbers if necessary. Trying the sweater on now and “Design Process #4: Knitting…”

Tag: design process

Design Process #3: Casting On

Swatch and calculations done, I’m finally ready to start knitting. This is my favorite part! I usually write the pattern alongside the knitting of my “Design Process #3: Casting On”

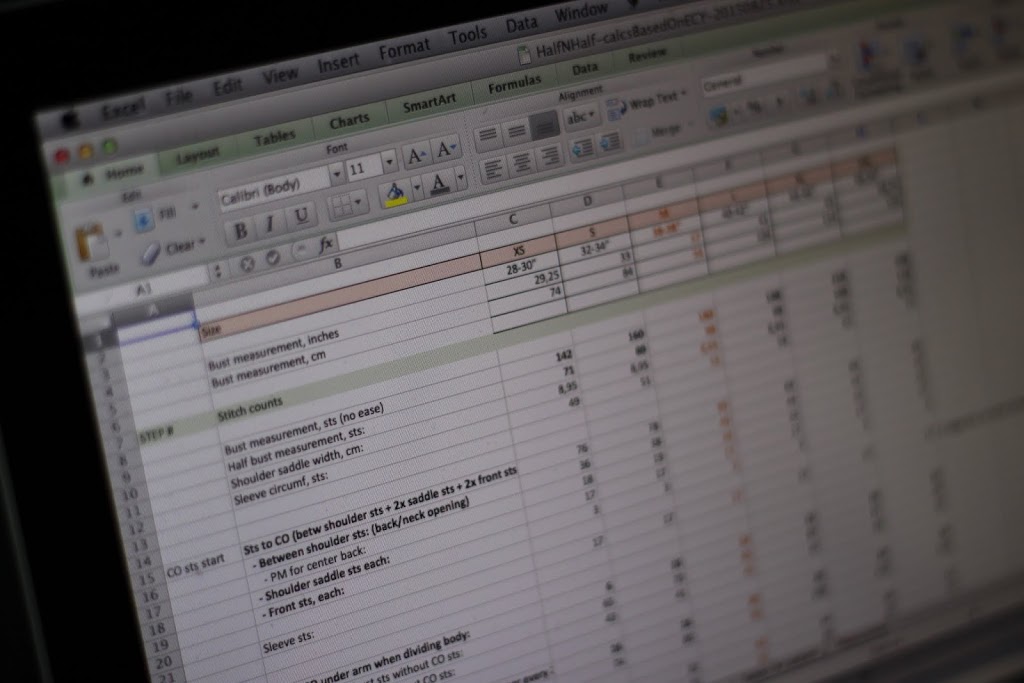

Design Process #2: Calculating

Having done my gauge swatch, it’s time to do some calculations. For the calculating, I use Excel spreadsheets. I could of course calculate everything by hand “Design Process #2: Calculating”

Design Process #1: Planning

For a long time, I have been wanting to share the process I (usually) go through when designing something. I say “usually”, as it can “Design Process #1: Planning”